Vehicle Suspensions and our Philosophy

What is a suspension?

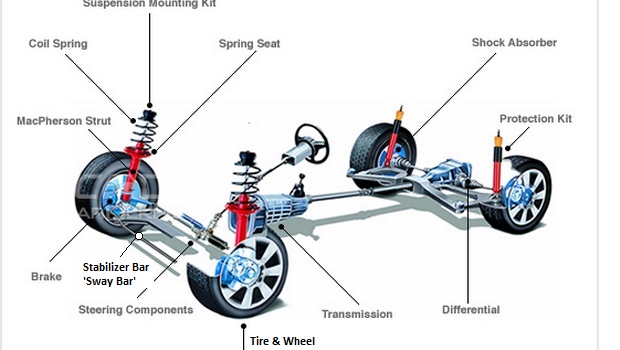

A vehicle's suspension is the system that interfaces between the car's chassis (with occupants and cargo) and the road through the wheels/tires (Reference 1).

The suspension components help the tires maintain their contact patch with the ground. In turn, through maintaing consistent contact with the ground and with sufficient response to driver inputs -through steering, accelerator, and brake - the suspension keeps you in control of the car.

As this reference indicates, the suspension's purpose is to promote occupant Comfort, maintain Safety with changing road and weather conditions, and aid Handling to adjust the driver's course along the road.

Suspension components include dampers*, springs, anti-sway bars, bushings, and control arms. The suspension's design and the interaction between its components determines whether the ride is smooth, harsh, or something in between.

Some suspensions are very simple (such as the leaf spring, found on horse-drawn carriages) and have been around for hundreds of years. Others are more recent developments, like the MacPherson strut as found on many passenger cars, or the double-wishbone system (more properly called 'short-long arm' (SLA) or unequal-length control arm) as found on the 1990-2005 Miata, Honda S2000, Lotus Elise, etc. There are exotic forms of suspension for specific application but most suspension fall into a category of independent vs. dependent suspension. A major goal of proper suspension design is to maintain independence of an independent suspension or else turn it into that old-fashioned horse-drawn carriage!

The double-wishbone suspension design is the most effective for optimizing tire contact the most popular form used on most production sports cars although multi-link suspensions (as used on newer Honda Civics and the 2006+ Mazda MX5) are gaining popularity due to their own design advantages. Some images related to the Miata suspension are below. Credit to Keith Tanner at FM for providing these, which we've edited for clarity.

As this reference indicates, the suspension's purpose is to promote occupant Comfort, maintain Safety with changing road and weather conditions, and aid Handling to adjust the driver's course along the road.

Suspension components include dampers*, springs, anti-sway bars, bushings, and control arms. The suspension's design and the interaction between its components determines whether the ride is smooth, harsh, or something in between.

Some suspensions are very simple (such as the leaf spring, found on horse-drawn carriages) and have been around for hundreds of years. Others are more recent developments, like the MacPherson strut as found on many passenger cars, or the double-wishbone system (more properly called 'short-long arm' (SLA) or unequal-length control arm) as found on the 1990-2005 Miata, Honda S2000, Lotus Elise, etc. There are exotic forms of suspension for specific application but most suspension fall into a category of independent vs. dependent suspension. A major goal of proper suspension design is to maintain independence of an independent suspension or else turn it into that old-fashioned horse-drawn carriage!

The double-wishbone suspension design is the most effective for optimizing tire contact the most popular form used on most production sports cars although multi-link suspensions (as used on newer Honda Civics and the 2006+ Mazda MX5) are gaining popularity due to their own design advantages. Some images related to the Miata suspension are below. Credit to Keith Tanner at FM for providing these, which we've edited for clarity.

1990-1997 Miata shock assembly exploded view

1999-2005 Miata shock assembly exploded view

Overview of vehicle running gear components including suspension (front MacPherson strut design is shown)

1999 Miata front suspension diagram, colored to show component locations (provided by Keith Tanner, Flyin Miata)

At the top levels of technology, race cars such as those found in Formula 1 use even more radical designs. The goal remains the same - to control the

contact patch of the tires to maintain traction with the and ensure for driver has control of the vehicle.

*NOTE: Dampers (NOT 'dampeners') are the correct term for what many people (myself included) often call shock absorbers. A damper generates a force based on the velocity of the damper rod/piston. A dampener is what you use to water your plants. It disturbs me when I see someone, especially a vendor, refer to a 'dampener' since I assume their dampers leak or they are selling garden hoses. We don't sell dampeners - try Home Depot, OSH, or Lowe's.

*NOTE: Dampers (NOT 'dampeners') are the correct term for what many people (myself included) often call shock absorbers. A damper generates a force based on the velocity of the damper rod/piston. A dampener is what you use to water your plants. It disturbs me when I see someone, especially a vendor, refer to a 'dampener' since I assume their dampers leak or they are selling garden hoses. We don't sell dampeners - try Home Depot, OSH, or Lowe's.

Why focus on suspensions?

Most races are not won by the car with the most horsepower, but the car with the best overall grip and handling. If you concentrate on making the tire-to-ground interface as efficient as possible, you will maximize the available grip. With more grip comes more confidence and usually more ride comfort. You know the feeling of being in a big car on the freeway and not thinking you're going all that fast, but the speedometer reads well above the legal limit?

That comes from a comfortable and grippy suspension. It may not be the best handling/responding since it's a big car, but the feel can be very confidence-inspiring, and once you have experienced it, nothing else will compare. Some of the finest cars in the world have suspensions we can only dream about. But there are some simple but vital principles that can help turn even a vintage sportscar into a poised, comfortable, confident luxury machine. Think M5, or SLK, or even higher-end. Our goal is to bring that confidence-inspiring technology to an attainable level.

That comes from a comfortable and grippy suspension. It may not be the best handling/responding since it's a big car, but the feel can be very confidence-inspiring, and once you have experienced it, nothing else will compare. Some of the finest cars in the world have suspensions we can only dream about. But there are some simple but vital principles that can help turn even a vintage sportscar into a poised, comfortable, confident luxury machine. Think M5, or SLK, or even higher-end. Our goal is to bring that confidence-inspiring technology to an attainable level.

What makes the Miata special?

The 1990-2005 Mazda MX-5 Miata uses a double-wishbone suspension. The 2006+ Mazda MX-5 uses a double-wishbone design at the front but a more sophisticated multi-link (5 link) suspension at the rear which gives more control over wheel 'toe' for greater handling stability. Every MX5 since the birth of the line follows nearly an ideal formula for a sports car - as low weight as possible, rear-wheel drive, with a suspension that helps keep the tires in optimal contact with the road without requiring excessively stiff springs or sway bars.

The double-wishbone suspension has the attribute that, as the chassis rolls, the suspension changes the angle of the tires to compensate for some of that roll. Nothing is perfect in life so the suspension's camber gain (which is negative) can't fully compensate for the camber loss (which is positive) caused by body roll. While not 100%, a double-wishbone or multi-link design is much more effective at keeping the tire flatter (and maximize grip better) than a MacPherson strut or other lower-cost designs. The strut-type suspension is found on most production cars since it has a lower material cost and loss of cabin space to implement. The selection of a double-wishbone or 'short-long arm' (SLA) suspension is a victory of engineers over accountants, and rumor has it that the Miata *almost* got a MacPherson strut suspension (like the cool but not iconic Toyota MR2 of the same era). The engineers won out and thanks to their steady-fast efforts, we have the most nimble and capable sports car in the world, with a true sports car suspension geometry.

The double-wishbone suspension has the attribute that, as the chassis rolls, the suspension changes the angle of the tires to compensate for some of that roll. Nothing is perfect in life so the suspension's camber gain (which is negative) can't fully compensate for the camber loss (which is positive) caused by body roll. While not 100%, a double-wishbone or multi-link design is much more effective at keeping the tire flatter (and maximize grip better) than a MacPherson strut or other lower-cost designs. The strut-type suspension is found on most production cars since it has a lower material cost and loss of cabin space to implement. The selection of a double-wishbone or 'short-long arm' (SLA) suspension is a victory of engineers over accountants, and rumor has it that the Miata *almost* got a MacPherson strut suspension (like the cool but not iconic Toyota MR2 of the same era). The engineers won out and thanks to their steady-fast efforts, we have the most nimble and capable sports car in the world, with a true sports car suspension geometry.

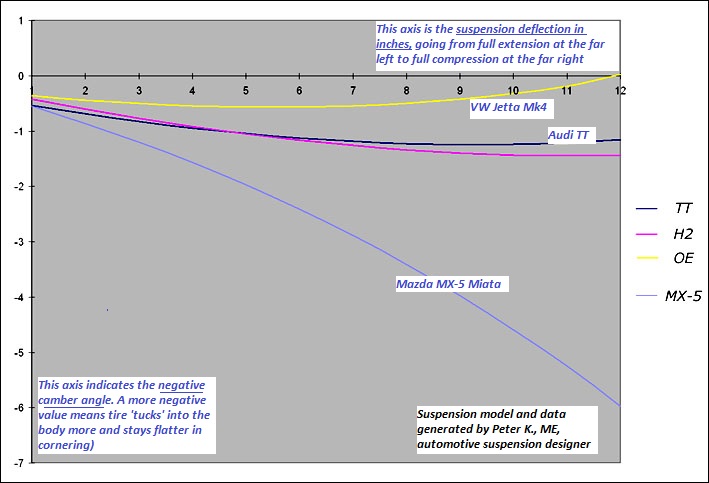

Above is a graphical representation of how the SLA ('short-long arm') or 'double-wishbone' suspension of a Miata (light blue lower curve) increases the tire's vertical angle (negative means the tire points more toward the body which keeps the tire in flatter contact with the ground). Compare that abundant negative camber gain to a few MacPherson strut cars (Volkswagen and Audi TT).

You can see how the Miata has a dramatic gain of negative camber which improves traction and cornering limits without requiring too much stiffness from the springs and sway bars.

Degrees of negative camber angle are the vertical y-axis, relative ride height on the horizontal x-axis. You can see that up to a point, the Miata suspension (blue curve) will gain nearly 0.5 deg of camber per degree of body roll. If you can start with, say, -1.0 to -2.0 deg camber when the car is stationary (static camber), and then the car rolls 4 degs in a turn, you can maintain a reasonable contact patch. This promotes better grip, better tire wear, and more predictable handling than a car with MacPherson struts.

My friend Peter, who generated these graphs, almost cries each time he looks at them - "such beautiful camber curves the Miata has!". I admit, he's European and loves opera so there might be some embellishment, but sometimes you have to step back to really appreciate how close to perfect the Miata really is! It shares and even in some ways improves upon the same double-wishbone suspension of the Corvette, Ferrari, Honda S2000, and certainly the Lotus Elise (which actually has very poor camber gain compared to the Miata!).

Once behind the wheel and moving through a few turns, you start to feel how connected the car is to your hands and mind. Without sounding too fanciful, the connection is almost telepathic. People fall in love for many reasons, but I believe appreciating the other's soul - their essence - is the highest compliment. It is the Miata's soul that most of us fall in love with, regardless of color, options, or age. The Miata's designers had a philosophy in mind and every time we get behind the wheel we are reaffirming it - that good things come in small packages!

While we love the Miata we're also relentless perfectionists. The first generation was designed in the late 80s and bump stop materials have dramatically improved since then. We found that micro-cellular polyurethane bump stop would be more forgiving under initial compression and allow additional suspension travel for more predictable handling while at a lower ride height. Also, the first generation Miata did not receive 'Flat Ride' tuning, unlike the second (NB 99-05), third (NC 06-15), or fourth (ND 16+). When we engage in an FCM Elite suspension build, we emphasize the need for this industry-standard tuning philosophy. There are many benefits to using Flat Ride which we begin to describe in our blog post about 'common sense suspension tuning' to achieve Ride Harmony along with our video 'What is Flat Ride and Why Should You Care?' and especially our follow-up video 'Why Flat Ride Matters? A fascinating road test with NO damping!' Do check them out! We want to make the best handling, more user-friendly, and durable sports car ever made EVEN BETTER plus tailor it as your unique needs require. This process of optimization is the uniqueness and benefit of becoming part of the FCM Elite.

NOTE: As of April, 2008, Peter (pyce on Miataforum) now owns a '93LE!

What is your philosophy about suspension tuning?

In a short expression, a suspension should be made to swear to the Hippocratic Oath - "Do No Harm." This is the foundation of our philosophy of Ride Harmony. If you'd like to read more about this topic and ask questions, visit our blog The Perfect Ride starting with this post on 'common sense suspension tuning.'

How would a suspension actually do harm, or disrespect the driver, occupants, and cargo? First, by improperly isolating them from a variety of potential road disturbances and second, by over-reacting to that stimulus even by accident or by design. To more specifically expand upon this theme of 'Do No Harm', I need to define a few important terms, because in general they tie strongly into general suspension design and in particular, into how we implement design ours. These terms are:

I won't talk about this in too much detail but they are important to understand. The first two most people are comfortable with, the last perhaps not as much. We usually talk about speed and not velocity. However, they are related. Speed is 'how fast', like discussions about the speed limit. Velocity is 'how fast' and 'what direction.' If you specify a direction, ("I'm heading out of LA and driving to Vegas, baby!") then you have turned speed into velocity.

Acceleration is the change in velocity over time. You get acceleration when you start off from a red light, apply the brakes, or when you're turning into a corner (even if your speedometer shows a constant value). If you change velocity, either by slowing down, speeding up, or turning, you now have an acceleration. Acceleration simply means a change in velocity.

What does this have to do with suspensions and how we tune cars? Most automotive designers strive to provide a comfortable ride for passengers while giving the driver a sense of confidence in the vehicle - a fine balance. The human nervous system doesn't have speed sensors, but it does have acceleration sensors. Often based on hype, we've come to expect that a sports car will feel very busy. Ironically, it's very easy to add suspension components that make your car slower and less safe than it was from the factory.

Changes in acceleration are called jerk. It's a good description of what it actually feels like. You're in a steady turn and suddenly have to swerve (or 'jerk' the wheel) to avoid a deer. You were accelerating at one rate, then that acceleration changed. It's disconcerting to passengers more than the driver, who's more concerned with avoiding whatever's in his way.

But jerk can happen in any possible direction the chassis can move and even combinations of two or more directions at once (pitch, yaw, roll, heave, etc.). Imagine all the directions of motion a ship at sea can move in and it makes sense why people get sea-sick (or car sick on windy roads). They're reacting to repeated changes in acceleration, or jerk.

How would a suspension actually do harm, or disrespect the driver, occupants, and cargo? First, by improperly isolating them from a variety of potential road disturbances and second, by over-reacting to that stimulus even by accident or by design. To more specifically expand upon this theme of 'Do No Harm', I need to define a few important terms, because in general they tie strongly into general suspension design and in particular, into how we implement design ours. These terms are:

- velocity

- acceleration

- jerk

I won't talk about this in too much detail but they are important to understand. The first two most people are comfortable with, the last perhaps not as much. We usually talk about speed and not velocity. However, they are related. Speed is 'how fast', like discussions about the speed limit. Velocity is 'how fast' and 'what direction.' If you specify a direction, ("I'm heading out of LA and driving to Vegas, baby!") then you have turned speed into velocity.

Acceleration is the change in velocity over time. You get acceleration when you start off from a red light, apply the brakes, or when you're turning into a corner (even if your speedometer shows a constant value). If you change velocity, either by slowing down, speeding up, or turning, you now have an acceleration. Acceleration simply means a change in velocity.

What does this have to do with suspensions and how we tune cars? Most automotive designers strive to provide a comfortable ride for passengers while giving the driver a sense of confidence in the vehicle - a fine balance. The human nervous system doesn't have speed sensors, but it does have acceleration sensors. Often based on hype, we've come to expect that a sports car will feel very busy. Ironically, it's very easy to add suspension components that make your car slower and less safe than it was from the factory.

Changes in acceleration are called jerk. It's a good description of what it actually feels like. You're in a steady turn and suddenly have to swerve (or 'jerk' the wheel) to avoid a deer. You were accelerating at one rate, then that acceleration changed. It's disconcerting to passengers more than the driver, who's more concerned with avoiding whatever's in his way.

But jerk can happen in any possible direction the chassis can move and even combinations of two or more directions at once (pitch, yaw, roll, heave, etc.). Imagine all the directions of motion a ship at sea can move in and it makes sense why people get sea-sick (or car sick on windy roads). They're reacting to repeated changes in acceleration, or jerk.

That's all very nice, but can you bring it together for me?

I'm working on it! Like my personal odyssey in the world of suspension design and optimization, sharing my understanding with you is a process, not a goal to rush for. There is a goal - a light at the end of the tunnel - but to move through the darkness of the tunnel you have to clear away misception and falsehood which requires careful and deliberate action. But I can see the light ahead...

Our goal echoes that of any Quality vehicle suspension designer or optimizer: to minimize the uncomfortable and de-stabilizing sensation of 'jerk' for our customers. Reference 1, Reference 2. We accomplish this minimization of jerk (i.e. the rate of change of acceleration, as defined by convention and shown in Reference 1) through balancing the affect of suspension components so they work well together, smoothly absorbing the worst road imperfections while utilizing sufficient spring rate, sway bar stiffness, and damping force to provide for good driver control, plus to ensure overall vehicle stability on the road. This motto is a guiding principle in our design efforts:

Our goal echoes that of any Quality vehicle suspension designer or optimizer: to minimize the uncomfortable and de-stabilizing sensation of 'jerk' for our customers. Reference 1, Reference 2. We accomplish this minimization of jerk (i.e. the rate of change of acceleration, as defined by convention and shown in Reference 1) through balancing the affect of suspension components so they work well together, smoothly absorbing the worst road imperfections while utilizing sufficient spring rate, sway bar stiffness, and damping force to provide for good driver control, plus to ensure overall vehicle stability on the road. This motto is a guiding principle in our design efforts:

Perfection is achieved, not when there is nothing more to add, but when there is nothing left to take away - Antoine de Saint-Exupery

I see the interconnectedness of the three dimensions of suspension tuning with an eye toward minimization. Together this makes it a more spiritual pursuit than simply a mechanical one. The ability to support and respect the human occupants is a crucial aspect of achieving Ride Harmony. This pursuit has high ideals although is grounded in Real-World physics. Physics deals with understanding the way things are, so by saying 'Real-World physics', I mean engaging in a feedback loop of qualitative observation of the existing suspension behaviors, quantitative evaluation of the existing suspension components and relationship on the vehicle, developing a practical suspension model, modifying or changing suspension components, creating a new baseline suspension behavior, testing the changes in the Real-World, and refining my suspension model to include more subtle behaviors. All of this is to explore vehicle suspension optimization through a belief, now grounded in experience, that 'The Perfect Ride' is indeed possible, and closer to realizing than you may think.

The continuous discovering and refining of principles that govern Ride Harmony has taken us in directions that run counter to 'textbook knowledge', or confining engineering methods. Those methods focus on refining design 'rules' for a given application often ignoring potential relationships with other applications. For example, an engineer may assume off-road suspensions have little in common with race track suspensions, or not enough to warrant investigation and refinement. However, our practical, Real-World physics-based approach will indeed seek connections that unify each application. When the common goal is to minimize jerk, maximize tire contact patch, and maintain vehicle control, the objectives of a rally car suspension and a Porsche Cup Car are amazingly similar, even if the exact implementation may be different.

Actualizing our philosophy also creates a natural, intuitive feedback path to the driver. We are able to increase confidence in the vehicle capabilities - plus actually increase those capabilities - without resorting to artifically increasing 'feel' (jerk) to simulate improved performance which is what many 'sport' suspensions do either from the automaker directly or available through the aftermarket. You can trick the brain into believing you're having an exciting experience (like a rollercoaster tossing you around). The rollercoaster is firmly connected to a track that can varyin wildly in 3-dimensional space. Each rider participates in the thrilling experience with the assumption that they are safe and it's therefore it's okay to feel temporarily scared in their body because in the back of their mind, they trst they're safe.

However, the Real-World is not an amusement park ride and there is no guarantee the road won't surprise you in very uncomfortable ways. There are other drivers to navigate around, and unexpected obstacles or changing surface conditions to manage. What gives a fun feeling when you're in a controlled environment ('jerking' around on a rollercoaster, or bumper cars) becomes very disturbing outside the amusement park. This is why I am so strongly opposed to the design of 'sporty' suspensions that mimic these feelings, whether intentional or by accident. A short test drive might feel like a fun and exciting new experience, but once that 'falling in love' period ends you have to live with your vehicle and all is behaviors.

Don't be fooled into the 'showroom test drive experience'. In the Real-World, calm and smooth management of the road is required to create peace of mind through an intelligent, compassionately design dance between your -> your vehicle -> the tires -> the road. A vehicle suspension must behave more like two salsa dancers in dynamic balance vs. two wrestlers locked in battle. If you try and battle the ground, the ground will always win. So we must literally 'elevate' ourselves above the ground,which is to actualy 'suspend' ourselves, via proper use of the suspension's capability to do just that! I have written so much on this and it feels necessary to do so, since our perceptions have been painted (whether through omission or intention) to believe a fast car with high handling potential must also be rough. Or, that some fancy and expensive electronic and hydraulic wizardry is required to give us the very best smooth and nimble ride (e.g. the trend toward complex magneto-rheologic {MR} and fast-switching semi-active dampers, or self-leveling suspension systems).

We can very easily be fooled into believing that more and more technology is the answer, when I have absolute certainty that is not the case. The solution isn't more gimics and gadgets, but better implementation of existing methods to the specific purpose at hand and the customer needs. How can I say with confidence that 'less is more'? From the results of over a decade of building unique and optimized suspensions for my customer (as optimized as my understanding and current methods allowed). Through customer and my experience plus common sense and affirmation of engineering papers themselves. Through the most wonderfully unexpected experience of riding in a vehicle with dead dampers! I know The areas of the world that can least afford to deal with complex suspension technology, or non-rebuildable-throw-away dampers are the ones who most need an elegant solution that is indeed durable, adaptable, configurable. This is what it means to truly show respect to our brothers and sisters - that we know something they don't know and the way to demonstrate love is to act in a way that is in their best interests. Yes, I am an idealist (aren't you?) But there's also a solid theoretical body-of-work and significant real-world results to back it up!

We believe a sensitive driver wants the highest possible grip with the best possible response to his control inputs. He wants to have the confidence to navigate a series of turns as smoothly as possible, whether for the best time or simply his own enjoyment. We realize this means finding a compromise between ultimate grip and ultimate feel. But this compromise is not as extreme as some would have you believe. We've proven this to ourselves and to our many FCM Elite customers. This is where the art of suspension tuning meets the magic of real-world physics.

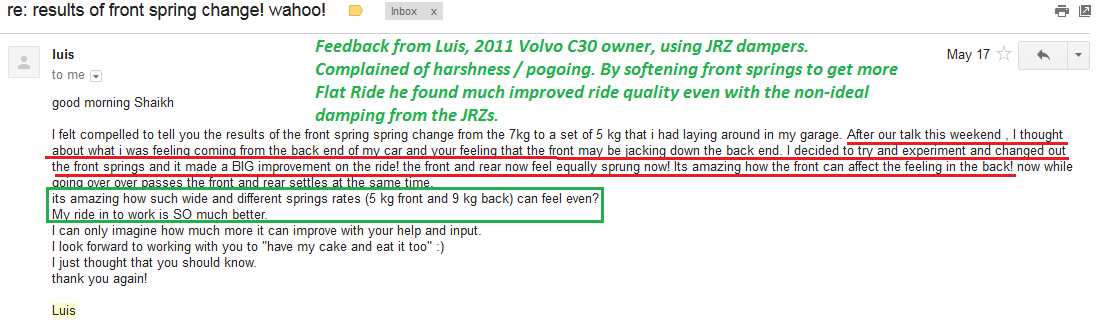

We're proud that our philosophy of Ride Harmony and techniques we understand and develop find parallels in development of high-end luxury and top-level racecars. Here's feedback from a customer using a different vendor's suspension but who was able to apply a few Ride Harmony concepts to improve his results.

The continuous discovering and refining of principles that govern Ride Harmony has taken us in directions that run counter to 'textbook knowledge', or confining engineering methods. Those methods focus on refining design 'rules' for a given application often ignoring potential relationships with other applications. For example, an engineer may assume off-road suspensions have little in common with race track suspensions, or not enough to warrant investigation and refinement. However, our practical, Real-World physics-based approach will indeed seek connections that unify each application. When the common goal is to minimize jerk, maximize tire contact patch, and maintain vehicle control, the objectives of a rally car suspension and a Porsche Cup Car are amazingly similar, even if the exact implementation may be different.

Actualizing our philosophy also creates a natural, intuitive feedback path to the driver. We are able to increase confidence in the vehicle capabilities - plus actually increase those capabilities - without resorting to artifically increasing 'feel' (jerk) to simulate improved performance which is what many 'sport' suspensions do either from the automaker directly or available through the aftermarket. You can trick the brain into believing you're having an exciting experience (like a rollercoaster tossing you around). The rollercoaster is firmly connected to a track that can varyin wildly in 3-dimensional space. Each rider participates in the thrilling experience with the assumption that they are safe and it's therefore it's okay to feel temporarily scared in their body because in the back of their mind, they trst they're safe.

However, the Real-World is not an amusement park ride and there is no guarantee the road won't surprise you in very uncomfortable ways. There are other drivers to navigate around, and unexpected obstacles or changing surface conditions to manage. What gives a fun feeling when you're in a controlled environment ('jerking' around on a rollercoaster, or bumper cars) becomes very disturbing outside the amusement park. This is why I am so strongly opposed to the design of 'sporty' suspensions that mimic these feelings, whether intentional or by accident. A short test drive might feel like a fun and exciting new experience, but once that 'falling in love' period ends you have to live with your vehicle and all is behaviors.

Don't be fooled into the 'showroom test drive experience'. In the Real-World, calm and smooth management of the road is required to create peace of mind through an intelligent, compassionately design dance between your -> your vehicle -> the tires -> the road. A vehicle suspension must behave more like two salsa dancers in dynamic balance vs. two wrestlers locked in battle. If you try and battle the ground, the ground will always win. So we must literally 'elevate' ourselves above the ground,which is to actualy 'suspend' ourselves, via proper use of the suspension's capability to do just that! I have written so much on this and it feels necessary to do so, since our perceptions have been painted (whether through omission or intention) to believe a fast car with high handling potential must also be rough. Or, that some fancy and expensive electronic and hydraulic wizardry is required to give us the very best smooth and nimble ride (e.g. the trend toward complex magneto-rheologic {MR} and fast-switching semi-active dampers, or self-leveling suspension systems).

We can very easily be fooled into believing that more and more technology is the answer, when I have absolute certainty that is not the case. The solution isn't more gimics and gadgets, but better implementation of existing methods to the specific purpose at hand and the customer needs. How can I say with confidence that 'less is more'? From the results of over a decade of building unique and optimized suspensions for my customer (as optimized as my understanding and current methods allowed). Through customer and my experience plus common sense and affirmation of engineering papers themselves. Through the most wonderfully unexpected experience of riding in a vehicle with dead dampers! I know The areas of the world that can least afford to deal with complex suspension technology, or non-rebuildable-throw-away dampers are the ones who most need an elegant solution that is indeed durable, adaptable, configurable. This is what it means to truly show respect to our brothers and sisters - that we know something they don't know and the way to demonstrate love is to act in a way that is in their best interests. Yes, I am an idealist (aren't you?) But there's also a solid theoretical body-of-work and significant real-world results to back it up!

We believe a sensitive driver wants the highest possible grip with the best possible response to his control inputs. He wants to have the confidence to navigate a series of turns as smoothly as possible, whether for the best time or simply his own enjoyment. We realize this means finding a compromise between ultimate grip and ultimate feel. But this compromise is not as extreme as some would have you believe. We've proven this to ourselves and to our many FCM Elite customers. This is where the art of suspension tuning meets the magic of real-world physics.

We're proud that our philosophy of Ride Harmony and techniques we understand and develop find parallels in development of high-end luxury and top-level racecars. Here's feedback from a customer using a different vendor's suspension but who was able to apply a few Ride Harmony concepts to improve his results.

"good morning Shaikh

I felt compelled to tell you the results of the front spring (rate) change from the 7kg to a set of 5 kg that I had laying around in my garage. After our talk this weekend, I thought about what I was feeling coming from the back end of my car and your feling that the front may be jacking down the back end. I decided to try and experiment and changed out the front springs and it made a BIG improvement on the ride! the front and rear now feeling equally sprung now!

Its amazing how the front can affect the feeling in the back! now while going over over passes the front and rear settles at the same time. its amazing how such wide and different spring rates (5 kg front and 9 kg back) can feel even?

My ride in to work is SO much better.

I can only imagine how much more it can improve with your help and input.

I look forward to working with you to 'have my cake and eat it too' :)

I just thought you should know.

thank you again!

-Luis (in Los Angeles, CA)"

On my preference for empirical / real-world models vs. 3D / CAD-generated models

In the majority of work I do through Fat Cat Motorsports, my focus is to make practical changes to those elements for maximum effect. When it comes to parameters such as roll centers, center of gravity, instant centers, detailed calculations of weight transfer, pitch / heave / roll modes and much more, one can study these subjects forever. I like to use the stock suspension geometry as a starting point and then empirically assess how the vehicle is behaving. While it's possible to interpret a model to 'feel' what a vehicle is doing, that is not as intuitive as actually DRIVING the vehicle and then working out what makes it behave the way it is. Often, the most dominant factors in the ride, safety, and handling come from the interaction between the spring, the sway bars, the dampers, and the bump stops. The roll centers, center of gravity, frequency modes, etc. are indeed very important but if we start with a new production car that has not had the ride height modified, or you keep the ride height constant during your empirical assessment, you can make very effective changes to improve the vehicle's behavior. When possible, do utilize a 3D model (created by you if possible or from someone qualified to do so) to add insight to your empirical assessment. While some people might make fun of this 'Excel-based' approach, there's no arguing with the results because I focus on 'how does the car work in the Real-World' not on what does a simulation say!

"Nature is far more complex than our models of her."

Therefore, I begin with observing our vehicle in its natural habit, the Real World we live in, and seek to make basic models of those behaviors. Then, as a final check, refer to theoretical / ideal case models for any important details I may have overlooked when creating my empirical model.

In NO suspension model I've seen are the bump stop behaviors included in the vehicle handling! Race car engineers typically leave the bump stop out ('it's non-linear, it's bad, throw it away!') yet every production car uses a bump stop. So how do you account for them in your modeling? I make a few reasonable assumptions about constant ride height, then note the FRC (front roll couple, or handling balance expressed as a percentage) in light cornering {not on the bump stops} vs. hard cornering {with maximum bump stop engagement}. This is where it's clear that many vehicles driven at 100% of their cornering limit exhibit different characteristics than at 50% or 70% of the limit. In a way, since I first started my adventures in suspension study and modification through changing bump stops, I always have them in mind as a crucial factor that is too-often overlooked by others. I have multiple video on the effect of changing bump stops and the impact on vehicle handling. Many testimonials from bump stop customers are presented here.

It makes sense for engineers who are responsible for multi-million dollar product lines to rely on careful modeling even before having prototypes made. This computer-aided revolution has taken leaps and bounds since the very early days of their use. The new Corvette C7 is an example of exceptional attention to detail and it shows in its capabilities. However, once those engineers have worked their magic and provided a great vehicle to exceed their customer's expectations, there is often something more that can be improved. I have never NOT found this to be the case! And it's through driving the vehicle and doing something as simple as watching my exit speed through a familiar clover leaf, or using a proprietary Ride Quality app I've co-developed to get a quantitative measure of the potential improvement that helps me determine what to change and why. I do my own modeling, you see, based on how the far fels but more importantly how lap times improve. I know that the softer the Ride Number becomes, the greater the cornering grip will be - because less 'jerk', less rate of change of acceleration will improve the tire's contact patch and that will translate into more road-holding.

So how do I conduct this process of ride characterization? By empirically, I have a few steps I follow:

Step 1 - Drive the vehicle and note nuances of handling or ride behaviors; how does it handle bumps / dips in the road of varying kinds? Does it feel stable at city speeds and then highway speeds? Does the ride quality improve the slower you go or the faster you go?

Step 2 - In a safe environment, observe how stable it is at the limit of cornering along with gathering useful data about the behavior such as tire temperatures, lateral acceleration ('cornering g'), shock travel, etc.

Step 3 - Remove the wheel and suspension spring to measure how much suspension travel is possible before the bump stop comes into play. Then, remove the bump stop, spring, and damper ('shock absorber') to characterize those with the appropriate instruments. A shock dynamometer is the perfct tool to measure damper performance, and also is useful for assessing bump stop behavior. Spring rates are usually best characterized first via a bounce measurement and second via a bench measurement (accounting for the vehicle's load to know how many spring coils or leafs are active). With a functioning damper on the vehicle, the 'true' spring rate is obscured by the presence of damping and other springs in the system which include the tire, dampers, bushings, and flex in other suspension members. Still, the bounce frequency measurement tells you something about how the vehicle's Ride Quality potential.

Step 4 - Once a fairly thorough empirical (though not fully 3D using AutoCAD or Solidworks!) model is generated, we can correlate some of the observed behaviors with measured quantities. For example, if the front bump stops are fairly long, firm, and - in cornering - engage sooner than the rear bump stops, the vehicle will exhibit a reluctance to follow the driver's steering input. In racing terms, we'd call this 'understeer', where the vehicle responds to the steering input LESS or UNDER what the driver is asking for. To make a vehicle more 'neutral steering' we could soften and shorten the front bump stops, or lengthen and stiffen the rear bump stops to make a simple and effective change. Mind you, this may not be appropriate for an average driver who may not have the skill to control a high-performance vehicle that is more capable than the factory intended. But for someone who is willing to take responsibility for safely piloting a more capable, better-handling vehicle, we have given oursleves a basic picture of what the suspension is doing dynamically.

Step 5 - We can put these measured elements together (physical quantities like bump stop length and density, spring rates, sway bar size, camber curves, available suspension travel, shock damping curves, etc.) and create a conceptual model of the vehicle's behavior. You get quantities such as the front roll couple % (also called 'FRC %') which measures the percent of weight transfer across the front axle. This number helps give a sense of the understeer or oversteer balance for the vehicle in that configuration. You can bounce use the direct 'bounce' measurements to get the actual ride frequencies (including damping) and see what the ride frequencies would be without damping (from the measured spring rate, motion ratios, corner weights).

"Nature is far more complex than our models of her."

Therefore, I begin with observing our vehicle in its natural habit, the Real World we live in, and seek to make basic models of those behaviors. Then, as a final check, refer to theoretical / ideal case models for any important details I may have overlooked when creating my empirical model.

In NO suspension model I've seen are the bump stop behaviors included in the vehicle handling! Race car engineers typically leave the bump stop out ('it's non-linear, it's bad, throw it away!') yet every production car uses a bump stop. So how do you account for them in your modeling? I make a few reasonable assumptions about constant ride height, then note the FRC (front roll couple, or handling balance expressed as a percentage) in light cornering {not on the bump stops} vs. hard cornering {with maximum bump stop engagement}. This is where it's clear that many vehicles driven at 100% of their cornering limit exhibit different characteristics than at 50% or 70% of the limit. In a way, since I first started my adventures in suspension study and modification through changing bump stops, I always have them in mind as a crucial factor that is too-often overlooked by others. I have multiple video on the effect of changing bump stops and the impact on vehicle handling. Many testimonials from bump stop customers are presented here.

It makes sense for engineers who are responsible for multi-million dollar product lines to rely on careful modeling even before having prototypes made. This computer-aided revolution has taken leaps and bounds since the very early days of their use. The new Corvette C7 is an example of exceptional attention to detail and it shows in its capabilities. However, once those engineers have worked their magic and provided a great vehicle to exceed their customer's expectations, there is often something more that can be improved. I have never NOT found this to be the case! And it's through driving the vehicle and doing something as simple as watching my exit speed through a familiar clover leaf, or using a proprietary Ride Quality app I've co-developed to get a quantitative measure of the potential improvement that helps me determine what to change and why. I do my own modeling, you see, based on how the far fels but more importantly how lap times improve. I know that the softer the Ride Number becomes, the greater the cornering grip will be - because less 'jerk', less rate of change of acceleration will improve the tire's contact patch and that will translate into more road-holding.

So how do I conduct this process of ride characterization? By empirically, I have a few steps I follow:

Step 1 - Drive the vehicle and note nuances of handling or ride behaviors; how does it handle bumps / dips in the road of varying kinds? Does it feel stable at city speeds and then highway speeds? Does the ride quality improve the slower you go or the faster you go?

Step 2 - In a safe environment, observe how stable it is at the limit of cornering along with gathering useful data about the behavior such as tire temperatures, lateral acceleration ('cornering g'), shock travel, etc.

Step 3 - Remove the wheel and suspension spring to measure how much suspension travel is possible before the bump stop comes into play. Then, remove the bump stop, spring, and damper ('shock absorber') to characterize those with the appropriate instruments. A shock dynamometer is the perfct tool to measure damper performance, and also is useful for assessing bump stop behavior. Spring rates are usually best characterized first via a bounce measurement and second via a bench measurement (accounting for the vehicle's load to know how many spring coils or leafs are active). With a functioning damper on the vehicle, the 'true' spring rate is obscured by the presence of damping and other springs in the system which include the tire, dampers, bushings, and flex in other suspension members. Still, the bounce frequency measurement tells you something about how the vehicle's Ride Quality potential.

Step 4 - Once a fairly thorough empirical (though not fully 3D using AutoCAD or Solidworks!) model is generated, we can correlate some of the observed behaviors with measured quantities. For example, if the front bump stops are fairly long, firm, and - in cornering - engage sooner than the rear bump stops, the vehicle will exhibit a reluctance to follow the driver's steering input. In racing terms, we'd call this 'understeer', where the vehicle responds to the steering input LESS or UNDER what the driver is asking for. To make a vehicle more 'neutral steering' we could soften and shorten the front bump stops, or lengthen and stiffen the rear bump stops to make a simple and effective change. Mind you, this may not be appropriate for an average driver who may not have the skill to control a high-performance vehicle that is more capable than the factory intended. But for someone who is willing to take responsibility for safely piloting a more capable, better-handling vehicle, we have given oursleves a basic picture of what the suspension is doing dynamically.

Step 5 - We can put these measured elements together (physical quantities like bump stop length and density, spring rates, sway bar size, camber curves, available suspension travel, shock damping curves, etc.) and create a conceptual model of the vehicle's behavior. You get quantities such as the front roll couple % (also called 'FRC %') which measures the percent of weight transfer across the front axle. This number helps give a sense of the understeer or oversteer balance for the vehicle in that configuration. You can bounce use the direct 'bounce' measurements to get the actual ride frequencies (including damping) and see what the ride frequencies would be without damping (from the measured spring rate, motion ratios, corner weights).

Beginning with simplicity: the relationship between physics, mathematics, and engineering applies to vehicle suspension design

This approach, roughly outlined above, starts to unlock the different aspects of vehicle behavior in a way that's simpler to understand than having to apply years of Mechanical Engineer classes and computer models. You don't have to know exact roll centers, center of gravity, instant centers, etc. to get a reasonable understanding of your production vehicle before making any changes. If you keep your ride height fairly constant, then the most important thing to understand is what the tires are telling you (from handling behavior and tire temps), what your body tells you (about how smooth or rough the vehicle is behaving), and what your passengers are telling you (if they are happy or annoyed after being in the car with you!). Greater complexity can be introduced later to refine your understanding, but NOT taking basic measurements as from our Characterization Process is premature surrender. YOU, as an intelligent human being, have the ability to understand what your vehicle is doing, what you like and don't like about it, and the capacity to ask for changes that are best for YOU.

Through applying common sense to suspension characterization, I strive for a 'Middle of the Road' balance between theory and practice, between descriptive / ideal numbers and physically quantifiable behaviors. Mathematics and physics are designed to help explain the world we live in as well as possible (always an approximation!), not to bog us down in minute details. Truly effective engineering, while very technical in its details, must always be based on and beholden to the physics which give rise to the device. Physics is the loving parent of engineering, and through mathematics both express their understanding in the world. It's through my love for understanding fundamental concepts ('first principles') that I have come to understand the true purpose of suspension design and apply principles that maximize the engineer's specific efforts to create Ride Harmony.

Additional resources for the intrepid investigator

These are presentations I've found that help to clarify and deepen one's understanding of the theory and application of vehicle suspension design:

Basics of Automotive Technology - Sales Consultant Training Course, this is quite a gem and has great illustrations and practical explanation of the key aspects of an automobile; their breakdown is Power Train System (power plant and drive line), Running System (suspension, steering, and braking), and Comfort System (HVAC, AC, Heater system, Seating/Instruments, and Audio/Video/GPS).

Vehicle Lateral Load Transfer parts I_III_MAR13, with a clean explanation on slide 31 of how the wheel rates are calculated and why the motion ratio is squared when going from 'raw' spring rate to 'effective' wheel rate. Also a short explanation of motion ratio here from a builder on a Pontiac Fiero forum.

Suspension Lecture by Dr. Richard Hathaway, a very good presentation with explanations and calculations

Well-lauded suspension Lecture by Dr. Richard Hathaway, a very good presentation with explanations and calculations

Mass Properties and Automotive Vertical Acceleration by Brian Wiegand, PE excellent images on 'Flat Ride', pitch, beat frequencies in the suspension, etc.

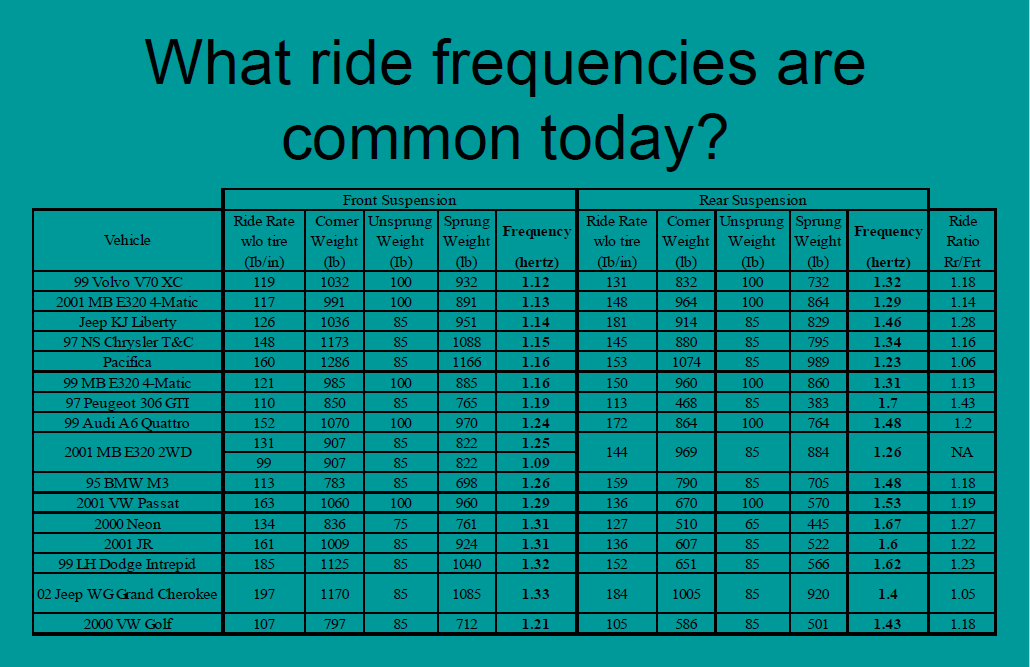

Collegiate Design Series - Suspension 101, a suspension lecture by Steve Lyman, Formula SAE Lead Design Judge, DaimlerChrysler Corporation, great quotes (Part 1, Part 2) by Maurice Olley on Ride Frequencies and 'Flat Ride' (referenced by Milliken and Milliken in 'Chassis Design: Principles and Analysis') and a very handy chart on ride frequencies for 16 production vehicles (shown below)!

Basics of Automotive Technology - Sales Consultant Training Course, this is quite a gem and has great illustrations and practical explanation of the key aspects of an automobile; their breakdown is Power Train System (power plant and drive line), Running System (suspension, steering, and braking), and Comfort System (HVAC, AC, Heater system, Seating/Instruments, and Audio/Video/GPS).

Vehicle Lateral Load Transfer parts I_III_MAR13, with a clean explanation on slide 31 of how the wheel rates are calculated and why the motion ratio is squared when going from 'raw' spring rate to 'effective' wheel rate. Also a short explanation of motion ratio here from a builder on a Pontiac Fiero forum.

Suspension Lecture by Dr. Richard Hathaway, a very good presentation with explanations and calculations

Well-lauded suspension Lecture by Dr. Richard Hathaway, a very good presentation with explanations and calculations

Mass Properties and Automotive Vertical Acceleration by Brian Wiegand, PE excellent images on 'Flat Ride', pitch, beat frequencies in the suspension, etc.

Collegiate Design Series - Suspension 101, a suspension lecture by Steve Lyman, Formula SAE Lead Design Judge, DaimlerChrysler Corporation, great quotes (Part 1, Part 2) by Maurice Olley on Ride Frequencies and 'Flat Ride' (referenced by Milliken and Milliken in 'Chassis Design: Principles and Analysis') and a very handy chart on ride frequencies for 16 production vehicles (shown below)!

Vehicle Dynamics by Ragnar Ledesma, PE, Ph.D., a very long and thorough presentation

Suspension system, good overview and images of the various parameters such as camber, caster, toe, king pin inclination, scrub radius, caster trail, and different suspension types with pros and cons.

Dynamic weight transfer in vehicle by Rohan Sahdev, a good presentation with useful graphics you may recognize from 'Tune to Win' by Carroll Smith, 'Race Car Vehicle Dynamics' by Milliken & Milliken, and 'Chassis Engineering' by Herb Adam.

Truck ride quality, HVTT12 Granlund, a very interesting presentation as it shows the cost in terms of damaged vehicles due to roads that are poorly maintained or designed with insufficient banking.

Suspension system in automobiles - good graphics and reasonable explanations, includes info on air bag suspensions pros vs. cons

Suspension system for FZ motorcycle suspension, I adjusted the title to something more useful. This is a very cool paper that goes into detail about damper details, design parameters for a monotube, stress calculations, wall thickness, etc.I like the 3-point summary of 'Objectives of Suspension System' being: Comfort, Safety, and Handling.

Active Suspension System

Article need for advanced suspension systems and this interesting comment about the need for advanced future suspension systems to be safety, comfort, durability with miminal costs and weights - exactly what we focus on through the use of rebuildable Bilstein monotube dampers!

Magic body control (a vision-based semi-active suspension system). A sequence of slides explaining what it is are here, #1, #2, #3, #4, #5, #6, #7, #8, #9, #10, with realistic merits/demerits including high cost and an honest comment that 'malfunctioning can lead to big collapse.'.

Electromagnetic Regenerative Shocks Absorbers, with a summary of pros vs. cons

Ride Quality: Smooth Sailing or Fasten Your Seat Belts? from the California Asphalt Paving Association, who repaved Mazda Raceway Laguna Seca!

Finite Element Analysis of Anti-Roll Bar to Optimize the Stiffness of the Anti-Roll Bar and the Body Roll

Optimization of a Passive Vehicle Suspension System for Ride Comfort Enhancement with Different Speeds Based on DOE Method

Basic ergonomics in automotive design, included as it's also new to me

Car Dynamics using Quarter Model and Passive Suspension, Part II: A Novel Simple Harmonic Hump